"for Michigan" (formichigan)

"for Michigan" (formichigan)

08/12/2016 at 20:57 • Filed to: General Motors, GMC acadia, New York times

2

2

30

30

"for Michigan" (formichigan)

"for Michigan" (formichigan)

08/12/2016 at 20:57 • Filed to: General Motors, GMC acadia, New York times |  2 2

|  30 30 |

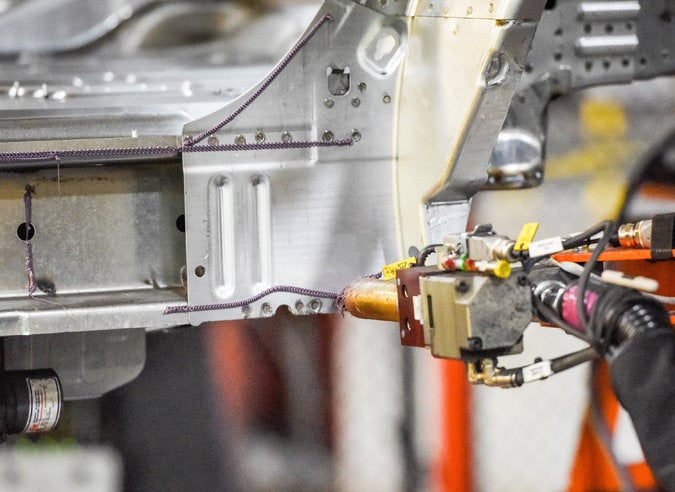

Photo Credit: Sanford Myers for General Motors

According to a !!!error: Indecipherable SUB-paragraph formatting!!! by The New York Times, GM is using aerospace-grade glue to assemble the new Acadia. Unlike rivets, which only bond where they’re inserted, the glue bonds the entire seam, forming a more rigid structure and allowing the individual pieces to be thinner and therefore lighter. GM says that weight savings from this technique make the new Acadia 700 lbs lighter than the outgoing model and raise the EPA estimated highway rating to 23 mpg.

Obviously building vehicles with glue is nothing new. Off the top of my head I know the Lotus Elise used glue to hold itself together with varying degrees of success. I seem to remember that the new 7-series uses something similar to include carbon fibre in its construction as well.

Still, that GM is using this kind of stuff to shave massive amounts of weight off of vehicles like the Acadia is awesome. We live in amazing times.

The Lurktastic Opponaught

> for Michigan

The Lurktastic Opponaught

> for Michigan

08/12/2016 at 21:00 |

|

Materials science FTW!

dogisbadob

> for Michigan

dogisbadob

> for Michigan

08/12/2016 at 21:03 |

|

The British use scotch tape and silly putty

Dru

> dogisbadob

Dru

> dogisbadob

08/12/2016 at 21:05 |

|

More like hilarious putty amirite????

BringBackTheCommodore

> for Michigan

BringBackTheCommodore

> for Michigan

08/12/2016 at 21:05 |

|

Pretty sticky subject, if you ask me. It makes it easy to maintain adherence to the topic.

Interesting method of assembly, especially for components that don’t require any disassembly. I wonder where this will go, and this definitely shows that small amounts of weight savings can really add up.

Flyboy is FAA certified insane

> for Michigan

Flyboy is FAA certified insane

> for Michigan

08/12/2016 at 21:06 |

|

I hope they’re not bonding steel structural items together. That glue is only for interior/ exterior panels, or so I thought.

Hell, if GM wants to go with the whole “airplane stuff is better than car stuff” they should stick to rivets. Everything on airplanes is riveted. Or used to be. Composite components are now obviously glued. But aluminum is always riveted.

dogisbadob

> Dru

dogisbadob

> Dru

08/12/2016 at 21:11 |

|

especially when it melts during the warranty period :p

DipodomysDeserti

> for Michigan

DipodomysDeserti

> for Michigan

08/12/2016 at 21:11 |

|

Uhhhh, I get 22 mpg highway on my 3,800 brick shaped Jeep Wrangler with a Chrysler engine from the ‘80s in it. How are these things getting such shitty gas mileage?

My in laws have one of these, they are complete pieces of shit.

Rusty Vandura - www.tinyurl.com/keepoppo

> for Michigan

Rusty Vandura - www.tinyurl.com/keepoppo

> for Michigan

08/12/2016 at 21:12 |

|

And lightweight air in the tires. And no spare.

Nerd-Vol

> for Michigan

Nerd-Vol

> for Michigan

08/12/2016 at 21:14 |

|

That is so fascinating. I would like to see this used in other cars. Could you imagine if they could make Miata 200 lbs lighter?

Birddog

> for Michigan

Birddog

> for Michigan

08/12/2016 at 21:16 |

|

Body shops are training in this stuff already. With GMs history of Beta testing the public? I can’t see 100 ways this goes sideways for them at all. Nope. Not at all.

As a plus, Skilled Welder wages just went up!

Frank Grimes

> for Michigan

Frank Grimes

> for Michigan

08/12/2016 at 21:18 |

|

so a non glued acadia had 700 lbs of weld wire?

dogisbadob

> DipodomysDeserti

dogisbadob

> DipodomysDeserti

08/12/2016 at 21:18 |

|

*AMC engine from the 50s :p

But yeah, too bad we don’t get the diesel Wrangler over here, and especially since thye’re made here! Finally acceptable mpg! And a Wrangler SRT8 would be awesome, too.

dogisbadob

> Nerd-Vol

dogisbadob

> Nerd-Vol

08/12/2016 at 21:23 |

|

Mazdas make themselves 200 lb lighter by rusting quick :p

TheRealBicycleBuck

> dogisbadob

TheRealBicycleBuck

> dogisbadob

08/12/2016 at 21:24 |

|

I doubt they would use Scotch tape. Perhaps duct tape and, judging by their wiring, copious amounts of electrical tape.

DipodomysDeserti

> dogisbadob

DipodomysDeserti

> dogisbadob

08/12/2016 at 21:25 |

|

Mine’s a 2011, so it has the “upgraded” 3.8L EGH V6. I have a carb’d SBC 350 sitting in my backyard right now that I’m tempted to shoehorn in.

for Michigan

> Frank Grimes

for Michigan

> Frank Grimes

08/12/2016 at 21:26 |

|

They say the glue allows for thinner, lighter metal pieces, which is where the majority of the weight savings come from.

Jesse Shaffer

> for Michigan

Jesse Shaffer

> for Michigan

08/12/2016 at 21:27 |

|

They added glue so they could take away metal from the car’s structure.

Great.

Rust and Dust - Oppositelock Forever

> for Michigan

Rust and Dust - Oppositelock Forever

> for Michigan

08/12/2016 at 21:27 |

|

Another benefit to adhesive bonding is the reduction in corrosion. Open space between spot welds on flanges is a great area for water and debris to become trapped and lead to rust. If memory serves correct, this is a 5 year old GM product. You can see dirt weeping from the rear apron panel seam to the strut tower, and a decent amount of corrosion between the front and rear apron panels. Adhesive bonding would have greatly reduced, if not entirely eliminated, the corrosion.

Manufacturers and body shops have used adhesives, as well as weld through adhesives (think weld through primer, but glue) for structural and exterior panels for awhile.

for Michigan

> Nerd-Vol

for Michigan

> Nerd-Vol

08/12/2016 at 21:27 |

|

Rumor has it the next Miata will make use of carbon fibre to lose even more weight. With a combination of cf and glue, maybe we could see the return of the sub-2000 lb sports car. I wouldn’t hold my breath for that, though.

for Michigan

> Birddog

for Michigan

> Birddog

08/12/2016 at 21:30 |

|

Yeah, being GM, I expect terrible results from pretty much any new technology they attempt to implement.

The Lurktastic Opponaught

> TheRealBicycleBuck

The Lurktastic Opponaught

> TheRealBicycleBuck

08/12/2016 at 21:30 |

|

You're closer than you think with the Scotch tape.

dogisbadob

> DipodomysDeserti

dogisbadob

> DipodomysDeserti

08/12/2016 at 21:34 |

|

cool if you don’t live in an emissions state (they usually frown on older engines in newer shells)

Birddog

> for Michigan

Birddog

> for Michigan

08/12/2016 at 21:56 |

|

Yup. They are leading in averages when you compare Successes to Failures though. But so is Jay Cutler if you go by statistics instead of reality.

DipodomysDeserti

> dogisbadob

DipodomysDeserti

> dogisbadob

08/12/2016 at 22:01 |

|

I do. I doubt they’d be able to tell the difference, though.

gmporschenut also a fan of hondas

> Flyboy is FAA certified insane

gmporschenut also a fan of hondas

> Flyboy is FAA certified insane

08/12/2016 at 22:09 |

|

Lotis glues the Elise chassis

dogisbadob

> DipodomysDeserti

dogisbadob

> DipodomysDeserti

08/12/2016 at 22:12 |

|

as long as it plugs into the obd :p

cluelessk

> Rust and Dust - Oppositelock Forever

cluelessk

> Rust and Dust - Oppositelock Forever

08/12/2016 at 22:15 |

|

Yup. Noticed a lot more cars going to glued wheel openings(quarter to outer wheelhouse.

It’s a pretty interesting time to be in the trade.

Flyboy is FAA certified insane

> gmporschenut also a fan of hondas

Flyboy is FAA certified insane

> gmporschenut also a fan of hondas

08/13/2016 at 00:06 |

|

The new one? Is it aluminum honeycomb and carbon?

Chinny Raccoon

> Flyboy is FAA certified insane

Chinny Raccoon

> Flyboy is FAA certified insane

08/13/2016 at 02:47 |

|

All Lotus models have used the bonded Aluminium chassis since the late 90s. It works.

Textured Soy Protein

> for Michigan

Textured Soy Protein

> for Michigan

08/15/2016 at 12:32 |

|

The Ferrari F40 is bonded carbon fiber, pretty slick for the late 80s. Note the green caulk-looking stuff.

Also I’m not sure what’s going on to the left of the gauge cluster but there might be 3 different radar detectors in this car haha.